Sustaining the Squadron: Sustainment Lessons-Learned at National Training Center

In February and early March 2013, I served as the logistics officer for a cavalry squadron (5th Squadron, 4th Cavalry Regiment) in an armored brigade combat team (ABCT) conducting a decisive-action training exercise at the National Training Center (NTC). I have never learned more in a two-week period than I did during our rotation. Our squadron was relearning how to engage near-peer conventional forces while also conducting wide-area security operations more in line with what we have done during the past 12 years. By training logistics during our platoon and troop-level training exercises at our home station of Fort Riley, KS, we went to NTC with some confidence and systems already in place. Many of these systems worked; many did not. However, by the end of the rotation at NTC, we had the utmost confidence that we would be able to sustain ourselves.

There are three main areas I believe need to be addressed: how we communicate our logistical situation, mission and requirements to higher, lower and adjacent units; where our logistical assets are located and who is located with them; and finally, how the current structure of our logistical units could be improved.

Communicating the logistics fight

During our training in preparation for NTC, the squadron ensured we did not “hand-wave” sustainment operations. Our forward maintenance teams moved with their troops just like they would at NTC, and we exercised our distribution platoon, so it was familiar with operating at night off the road. The squadron did not conduct maintenance in the motor pool during training at Fort Riley but, instead, pushed the unit maintenance collection point (UMCP) out into the prairie to operate in the field in support of all major squadron training events. Like most units, my unit made a determined effort to ensure that tactical and logistical training situations were always as realistic as possible. We also trained our logistical communications in much the same way in the squadron, so when we finally received all our equipment and were finally prepared to conduct the training at NTC, we had already rectified many of the kinks in our logistical communications from our extensive train-up at Fort Riley.

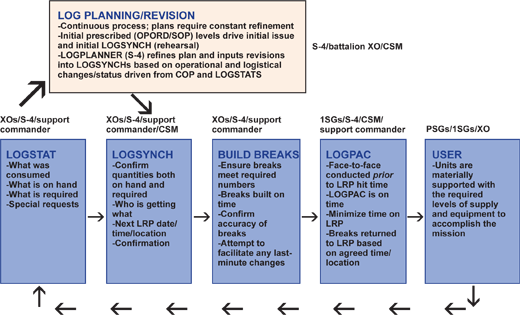

When we first began to train up for the NTC rotation, we did not have an established standard operating procedure (SOP) that prescribed or provided an outline of how we were supposed to communicate the logistical situation on the battlefield. This was no fault of previous staffs or chains of command. They stood the unit up and deployed it to Iraq twice where a decisive action-oriented SOP would have done little. Therefore, we had to start from scratch and get a working product in the roughly eight months we had prior to shipping our equipment to NTC. What worked for us was to keep the report formats as simple as possible and to ensure that the means in which we were communicating were available at the lowest level possible. The other sustainment leadership and I came together and discussed how the squadron could meet my information requirements in ways that were efficient for all parties. We continued to rework these report formats throughout the duration of the train-up and into the rotation. This led to constant refinement of our reporting procedures.

Beginning with humvee and Cavalry Fighting Vehicle (CFV) crew qualification, we laid the groundwork for how we would report and track the battlefield situation. We started with basic reports that described what the troops had on-hand in terms of fuel, food and ammunition once a day. Once we mastered that, we moved on to two times a day, and the reports became more specific. By the time we arrived at our platoon situational-training exercises (STX) in October, the troops were not only reporting what they had on hand, they were forecasting what they would need 24, 48 and 72 hours out. By the troop STX in November, the squadron had become efficient at the report. What we did wrong during our training at Fort Riley was that we did not require reports while the units were conducting tactical operations, and I should have done a much better job at requiring the reports in a timely manner.

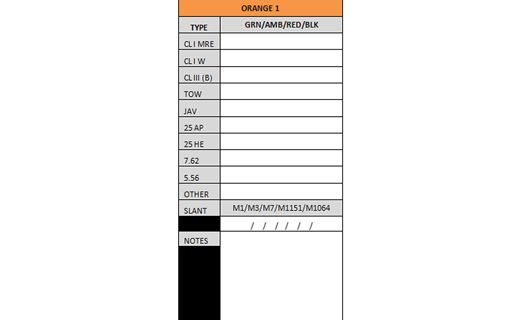

When we first began our decisive-action rotation, we had one logistical status called an “Orange 3.” This report was extremely detailed, but it was also very cumbersome. The troops were able to complete these reports once or twice a day if they were in static positions and not in contact with the enemy. What we quickly found out was that this was rarely the case. We needed to develop another report format that could provide me with all the information I needed so I could provide it to the squadron commander, other members of the staff and higher headquarters. We called what we came up with “Orange 1.” (See Figure 1.) It was short, just several lines, and contained only the most time-sensitive and pertinent information. The troop executive officers would report it to me every few hours when it was practical for them to do so. If they were in heavy contact with the enemy, it was only necessary to report changes that affected their ability to fight. Orange 1 contained the type of vehicles they had operational by type; their fuel, ammunition, water and food status; and any special or emergency requests they needed prior to receiving their next scheduled resupply.

By the end of our rotation, we became extremely efficient at reporting. Part of that was the creation of the refined reports; the other part was that timely and accurate reporting became emphasized by all levels of command. The troops would keep me constantly updated with the “Orange 1” report and, daily, or twice a day if possible, the “Orange 3” report. My comfort with my understanding of the logistical picture increased from Day 1 until the end of the exercise.

One example of a report we did not exercise during our home-station train-up was our battle-damage assessment report (Orange 5). This report came from the troops and provided me with information pertaining to one or more vehicles that had been “destroyed” by the enemy, so our higher headquarters could notionally replace them. I would then collect and analyze this information, prioritize the vehicles destroyed and send my own squadron-wide Orange 5 to the brigade. Early in the rotation, the amount of information the troops were sending was far too much and included such things as the actual vehicle serial numbers. This slowed down their reporting and my analysis of the reports, so the result was that our replacement vehicles were arriving far too late. By the end of the training rotation, we had shortened the report significantly so that it only included one piece of information: the vehicle’s bumper-number. From that one piece of information, I could ascertain all the other pertinent information, and the result was that we became so efficient that we had vehicles being replaced in the same fight in which they were destroyed.

The squadron’s logistic leaders were able to maintain near-constant situational awareness because we determined during the train-up at Fort Riley to keep most of our logistical reporting on a simple system that did not require battlefield Internet and that was readily available. We used the Blue Force Tracker (BFT), and it is excellent for communicating the logistics fight. It can be found in almost all tactical vehicles and command posts to send email-like typed messages, report formats and battlefield graphics. It also has a chatroom-type feature. All our “orange” reports were formatted like an Excel table in BFT, so all we had to do was refine those reports or create simpler reports like the “Orange 1” report.

During the initial stages of home-station training, we attempted to use other systems such as Battle Command Support and Sustainment System and the Command Post of the Future. Both these systems offer excellent capabilities, but we realized they were often in different locations than logistical leaders and had to be stationary for periods of time we deemed unacceptable.

I believe we began the rotation with some level of proficiency in this area due to the combination of already refined reports and a common system to report them. We also discovered another way to leverage the abilities of the BFT’s chatroom function; we could use it to conduct our daily logistical synchronization meetings. The chatroom function is just like it sounds. Different logistical leaders, typically the troop first sergeants, executive officers, forward-support-company (FSC) commander, maintenance officer and I would enter the chatroom in our BFT role-names. We would then conduct the meeting according to a predetermined format with the endstate being that all of us were on the same page in terms of our current situation, which led to the refinement of the next two resupply operations to ensure that, as their higher headquarters, we were providing everything in our power to provide.

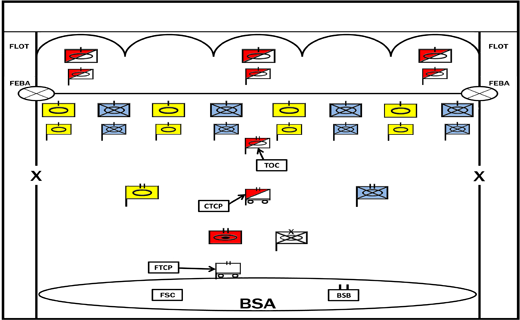

Placing logistics leaders and assets on the battlefield

Aside from communications, we also had to learn where to place our logistical leaders and assets on the battlefield as we transition to a battlefield that does not have preset forward-operating bases and other semi-permanent infrastructure. There are three primary logistical nodes and two medical nodes whose locations and composition need to be addressed. There are many different ways to achieve the same end; here are a few I saw work, and some I saw fail.

In much the same way as we trained communications, we began rehearsing and training our nodes during the humvee and CFV crew qualifications. The squadron leadership decided to bring our logistical nodes to the gunnery complex and exercise setting them up, tearing them down, moving them and doing it all over again. We did this despite the fact that the gunnery complex has hardstand buildings with built-in Internet, lighting and everything else one would ever need to conduct qualifications and plan for the next training event. The decision to operate out of the armored command vehicles and associated tents in the dirt of the motorpool proved invaluable.

When we moved on to the platoon and troop STXs, we became even more efficient at conducting sustainment operations with nodes, building protective obstacles and entry-control points, and conducting parallel planning with the tactical-operations center (TOC) located miles away. We also experimented with what our logistics nodes would actually look like by placing them in various locations with varying constructs. We learned some valuable lessons concerning what did not work during home-station training as well. For instance, during the squadron’s culminating training exercise, we gave each troop its own fuel truck to move with its troop trains. This proved far too cumbersome, and after the first day of the exercise, with some excellent advice from the troop first sergeants, we moved the fuel trucks back to the FSC.

The troop trains are the farthest forward logistical elements (FLE). These directly and continuously support their specific troops in terms of limited casualty evacuation, vehicle maintenance and supply. Typically, they would contain the troop’s first sergeant, with his vehicle, another casualty-evacuation vehicle and the troop’s administrative vehicle, and a small maintenance section that could perform rudimentary repairs and vehicle evacuation. That barebones organization is what worked the best for us.

When we got into trouble, it was usually because I would push additional assets – such as fuel (as mentioned above) or ammunition trucks – forward and not give the troop adequate time to return them. The result would be that those assets would not be able to replenish themselves or would be destroyed because they were large and cumbersome, and too close to the front lines. When that happened, they were not available to support the rest of the squadron for 12 to 24 hours, which complicated matters significantly. These troop trains were located anywhere from 250 to 500 meters behind the scout platoons on the front lines, or behind some form of terrain feature such as a ridgeline, which gave them protection from the enemy’s direct-fire weapon systems.

Moving backward, or away from, the front line, the next logistical element is the combat trains. This provides the entire squadron with a more robust supply and maintenance ability, close enough to the front line that it can support the reconnaissance troops in a expedient matter. The combat trains perform three more specific sustainment functions: maintenance, supply and sustainment command and control (C2).

For maintenance support, the combat trains contained the UMCP. This is really where most of the squadron’s organic maintenance assets, the actual systems and mechanics who could perform more sophisticated repairs, and another vehicle-recovery vehicle were located. The squadron maintenance officer was also located at the UMCP. As his title suggests, he is in charge of all maintenance operations within the squadron. We failed during the first half of our rotation to NTC to correctly position the UMCP. Instead of positioning it forward with the combat trains, we kept it farther back with the field trains.

This was probably our largest logistical failure during the entire rotation. It resulted in our complete inability to repair any of our vehicles that became damaged due to the simulated enemy fire or from actual breakdowns. We had some of our most critical vehicles sit in one place for nearly a week until we were finally able to move the UMCP forward. Once this was done, it took the mechanics several long and hard-working days to catch up, but for the last few days of the rotation, we were able to return critical combat power back to the front lines where it was needed.

We would also keep a small emergency resupply at the combat trains. For us, this consisted one fuel truck and one cargo vehicle with a trailer that carried the types of ammunition I anticipated would be of greatest importance. I guessed lucky and anticipated that mortar rounds and missile rounds for both the tube-launched, optically tracked, wire-guided (TOW) and Javelin systems would quickly come close to running out, and we used our emergency supply on three occasions. The emergency fuel supply was never used. I was able to respond quickly to the needs of the troops that required ammunition when we had the emergency resupply, and thus the combat trains located as close to centrally as practical. At one point, we had the combat trains located up to 15 kilometers from one of our troops. The result was that it took more than an hour to get the troops the mortar ammunition, and they nearly ran out while engaging the enemy. It is always said that logistics should be transparent to the battlefield; in other words, it should occur without having a negative impact, and I came close to violating that during that situation.

The remaining element we had at the combat trains was the combat trains’ command post. This included the headquarters and headquarters troop (HHT) leadership, the squadron personnel officer and often me (as well as the maintenance officer as described previously). The reason we decided to place this grouping of individuals here was because they are all critical to logistics functions. Maintenance, supply and medical personnel (covered by the HHT commander) are all represented. As such, much of the logistical specific mission planning could be accomplished in one place, and then I could move to the TOC closer to the front lines, where the rest of the staff was located, and input the logistical plan into the overall squadron order. It streamlined the planning process and worked well for us. This element also controlled the logistical operations for the squadron, to include planned resupply, vehicle recovery, casualty evacuation, emergency resupply, personnel replacement and processing, and chemical decontamination operations.

There were three main mistakes we made with the combat trains:

- First, as previously described, we did not always locate them so they could support the entire squadron. As a squadron, we fell into the trap of looking at it first as an alternate C2 node instead of a sustainment node. We quickly realized our error and continuously placed the combat trains in the correct place for most of the rotation.

- Second, also described previously, we began with a maintenance package that was too light in the combat trains. This had some severe consequences for a time, although, like all good units, we learned from our mistakes and rectified them.

- The third thing we could have done better was to do a better job manning the combat trains. We found it very difficult to secure ourselves and the assets we had, especially when the mechanics were working. I’m not suggesting half the TOC, but even six to eight Soldiers to aid in radio operator and guard duties would be a significant help.

- Also, the chemical officer should have served in the combat trains. This officer should have helped the planning process, as most of the chemical considerations were planned in the logistics portion of the order. This would also have provided another battle captain to assist in the C2 function of the combat trains, as the ones there “burned out” quickly while they served several roles simultaneously.

All that being said, I believe we did a good job overall with our combat trains. We learned, adjusted and became stronger through the course of the operation. The same can be said of our medical assets.

The rearmost logistical node for the squadron was our field trains. This was primarily composed of our FSC, Dakota Troop. Like the combat trains, we organized the field trains into several smaller elements, all under the command of the Dakota Troop commander. We placed the remaining maintenance team, the distribution platoon (supply, to include the other troop-supply sections), the maintenance-control section (which orders repair parts) and the Dakota Troop headquarters in the field trains.

We did a few things differently than most units with our field trains. First, we located them within the brigade-support area (BSA) with the rest of the brigade support battalion (BSB), as opposed to locating them forward in-between the BSA and the combat trains. The first reason we decided to do this was because they would have had a difficult time securing themselves had they been located alone. The cavalry squadron FSC is a smaller organization than in the combined-arms battalions, with fewer security assets, and by co-locating it with the BSB, our FSC had mutually supportive security. Dakota Troop now required fewer Soldiers to pull security, and the troop could still put its supply convoys on the road and conduct other tasks with more manpower.

The second and more important reason was so we would not have to rely on the BSB to “push” supplies to our field trains. We recognized that it was understrength in terms of manning and would have a difficult time supplying our field trains and the field trains of the other battalions. By placing Dakota Troop in the BSA, the troop could literally drive from its area to another area within the same perimeter to replenish its fuel trucks. Likewise, it could go to the ammunition holding area and draw the ammunition directly. The same can be said of the other supplies such as parts, food, water and nearly anything else. Having the troop commander there also assisted in direct coordination with the BSB leadership. We were able to work through a lot of confusion and smooth out a lot of issues that otherwise would have been much more complicated by keeping the field trains in the BSA.

One downfall to having located the field trains in the manner we did was the distance between the BSA and the rest of our squadron. Sometimes this distance exceeded 30 kilometers, which meant that it took Dakota more time to conduct resupply operations, which were often conducted at night using night-vision devices. That distance is a long way to drive at 10 miles per hour, then conduct a two-hour resupply, return and prepare to do it the next day. The other downfall was that we had no radio communication with the field trains for most of the rotation and had to exclusively rely on the BFT. While the BFT is a great system, there is nothing more clear than actually talking to another person.

The squadron, like most battalion-sized maneuver elements, has two nodes for medical support: a forward aid station (FAS) and a main aid station (MAS). For the squadron, composition of both is very similar. A large command track and its associated tents make up the actual aid station. Each one also had several ambulance vehicles to assist the troops in moving casualties from the front line to either the MAS or FAS or to the next level of care at the BSB. The medical platoon leader and surgeon would be at the MAS; the platoon sergeant and physician’s assistant were at the FAS. The mission responsibility of these locations is to stabilize casualties so they can be evacuated to the next level of care that can either treat or further stabilize.

We came away with one major learning point in terms of our FAS and MAS: they needed to be positioned to support the squadron in breadth, not depth. Our frontage often approached 30 kilometers, and at first we had a difficult time evacuating casualties to the FAS or MAS in the first hour, resulting in alarmingly high died-of-wounds rates. I believe the main reason was that we were, at first, tied to the idea of attaching those assets to the combat trains or TOC.

We quickly learned that course of action was not working. What we eventually ended up doing was assigning the FAS or MAS to one of the troops. For example, toward the end of the rotation, our Apache Troop was located to the north of the squadron’s area of operations. To remedy the situation, we assigned to FAS to Apache Troop. The downside was the FAS was closer to the front line and potentially in greater danger, but the plus side was apparent – Apache was able to successfully evacuate its casualties.

These are not definitive answers for where to place the logistical leadership and assets for a cavalry squadron, but where placed assets and leaders can make the situation work for us. Some of our sister units did things significantly different – like combining their field and combat trains – and, like us, learned and improved throughout the course of the rotation. One thing we could not change, but had to become clever on how to make it work, was the FSC’s organization.

FSC organization downfalls

The single greatest challenge we had during both our train-up to NTC and our rotation itself was the organic organization of the FSC assigned to cavalry squadrons. During training or, potentially, future real-world operations, this company cannot support the squadron without significant augmentation in terms of equipment and crews for the additional equipment. In terms of fuel trucks, supply trucks and security, there were significant gaps that need to be addressed, and we had to find interesting fixes to accomplish our mission.

There are three fuel trucks (M978s) found organically in the cavalry FSC. In terms of gallons-to-vehicle, having three M978s is sufficient to supply the squadron during maneuver operations. However, when the squadron is spread over an operating environment 30 kilometers wide by 40 kilometers deep, resupply cannot be done in a tactically feasible way without running resupply operations nearly 24 hours a day. Three M978s can support three reconnaissance troops, but this doesn’t take into account the TOC, combat trains and the need to have a forward emergency resupply of fuel. If a large fuel-thirsty attachment, like a tank company, is attached, there is no way three M978s will work. Yet, during our rotation, we had a tank company, and no one ever came close to running out of fuel.

How we accomplished this was by acquiring two more M978s from the BSB’s distribution company. The company couldn’t man the vehicles and we needed them, so it worked out for both sides. There was some significant gnashing of teeth from several parties about this, but in the end, we got our vehicles, and it did not take away from the capabilities of anyone else. I believe that by showing the necessity of these vehicles during our training at Fort Riley, we were able to convince all parties in the end that we needed them. We would be able to maintain one M978 forward, as discussed in defining the combat trains. The remaining four would operate out of the field trains and come forward during resupply convoys, typically once a day. Each reconnaissance troop would receive one M978, while the remaining one would resupply the TOC and/or combat trains while also acting as a reserve in case of mechanical issues or enemy activity toward the other three.

When a tank company was attached to us, which was the case for the entire rotation, it came with a logistical package of two more M978s as well as tank-specific mechanics. This is not an organizational concern but a point for logistical leaders that significant assets must come with adequate support if they are to be effective.

Incorporating lessons-learned from the past 12 years, we fought a complex enemy who had conventional assets as well as insurgent-type forces (the hybrid threat). With this in mind, it is hard to imagine a convoy of supply vehicles moving 40 kilometers without some form of protection. With the FSC’s current organization, that is exactly the case. There are no escort vehicles in the organization, and many of the supply vehicles that have the ability to mount weapon systems have not been issued the equipment to do so. To properly protect our assets, we assigned three unmanned humvees with gun turrets from the reconnaissance troops to Dakota Troop. Although this fixed the problem of security for our supply convoys, it created problems as well.

The field trains were located in the BSA but were not static for the length of the rotation. In fact, the BSA jumped (moved location) or pushed forward a FLE on four occasions, and each time Dakota jumped with it. The three escort humvees required nine Soldiers to man them. Those nine Soldiers could have manned an additional four cargo trucks of various types. As it stood, Dakota was unable to jump itself in one move and conduct resupply operations at the same time. This is a serious shortfall because as it stands, the field trains cannot remain mobile and accomplish their primary mission at the same time. Luckily, we were able to either make several trips while moving, or schedule resupply for non-conflicting times.

By either augmenting their organic organization to include escort vehicles, fielding the equipment to mount weapons on the supply vehicles, or increasing the number of supply vehicles, this problem could be addressed. We were able to successfully protect our convoys for the duration of the training event and to move everything we needed to move, but we were fortunate that the necessity to jump in one move, or to conduct resupply while jumping, was never faced.

Conclusion

NTC rotations are meant to be learning events, among other things, and for 5th Squadron, 4th Cavalry Regiment, the objective of learning from our successes and mistakes was achieved. There is no doubt in my mind that after the rotation, although not perfect, we were a much better unit than the one that put its equipment on the railcars in January 2013. Due to adaptability and by training logistics during all training events, we were able to sustain the squadron for the duration of the fight, and to do so in a more efficient manner as time progressed.

email

email print

print